Waste Management

The CARS waste management program focuses on the handling, treatment, and reuse of poultry litter. Arkansas is ranked #2 in poultry production in the nation and generates approximately 1.3 million metric tons of litter annually, all concentrated in the northwest region of the State. Since surplus poultry litter is no longer needed for crop fertilization, it becomes an environmental liability for poultry producers. Continuous application of poultry litter as fertilizer has been proved to lead to excessive amounts of plant extractable phosphorus (P) in the soil due to the high concentration of P relative to N in the litter. To address this issue, new waste disposal regulations were proposed in Arkansas in 2003, as a result of increased P runoff, requiring the export of surplus poultry litter outside this region. The Arkansas Soil and Water Corporation Commission (ASWCC) and local poultry integrators have offered to help subsidize the transport of excess poultry litter to eastern Arkansas, or to the neighboring states such as Oklahoma, Missouri, and Kansas for fertilizer use. Although this arrangement temporarily alleviates the immediate burden of the excessive litter nutrients on water pollution in Arkansas, it is not a reliable option in a long run due to the mounting transportation costs and the uncertainty of the subsidies in the near future that support the litter migration program. Given this situation, it is thus imperative to develop new technologies, or improve the existing technologies, to effectively treat poultry litter onsite in order to sustain the continuous growth of the poultry industry without polluting the environment. Besides, it has also been realized that tackling poultry litter needs a holistic strategy, i.e., it must be dealt with using a systems approach with zero and/or minimal waste loading to the environment. Therefore, the litter management research in CARS is highly needed to address the gaps in treatment technologies of poultry litter.

Waste Management Research

In the University of Arkansas Biological and Agricultural Engineering Department, Professor Jun Zhu has been working on sustainable methods of turning agricultural waste into valuable products. These projects include turning livestock and poultry waste into renewable energy sources and usable value-added products and developing technologies with which farmers can produce their own organic fertilizer. With the worldwide population projected to increase rapidly in the future, the demands on food are going to be greater. To meet the needs of our future generations for food and agricultural products, it is imperative to make agricultural production more efficient and sustainable by reusing the production wastes. Through effective waste treatment, waste recycling can be established that benefits farmers economically and the environment, and allows the agricultural process to become more sustainable.

Co-digestion poultry litter with other animal waste

Co-digesting poultry litter with another liquid manure can alleviate the low moisture content issue commonly existing in the litter that renders anaerobic digestion difficult to proceed. Similarly, many of the past reports mainly focused on the co-digestion of poultry manure (rather than litter) with different liquid manures such as swine and dairy manure, with little information related to poultry litter co-digestion. An exciting fact observed by past researchers was that the inclusion of poultry manure during anaerobic digestion of swine manure produced more methane and biogas than swine manure alone. However, some dilution of poultry manure was performed in this case, which could mask the results due to the reduced ammonia level in the substrate. Therefore, in this project, different mixing ratios of poultry litter and either liquid swine or dairy manure were investigated to determine the feasibility of this technology based on biogas production, methane content in biogas, volatile solids destruction, COD and BOD reduction. Another benefit of co-digesting these wastes is that the potential increase in the substrate C/N ratio can actually help improve the performance of the anaerobic digestion process. The best operating parameters including C/N ratio, temperature, pH, hydraulic retention time, and organic loading rate will also be determined for the digestion process.

Co-digesting poultry litter with another liquid manure can alleviate the low moisture content issue commonly existing in the litter that renders anaerobic digestion difficult to proceed. Similarly, many of the past reports mainly focused on the co-digestion of poultry manure (rather than litter) with different liquid manures such as swine and dairy manure, with little information related to poultry litter co-digestion. An exciting fact observed by past researchers was that the inclusion of poultry manure during anaerobic digestion of swine manure produced more methane and biogas than swine manure alone. However, some dilution of poultry manure was performed in this case, which could mask the results due to the reduced ammonia level in the substrate. Therefore, in this project, different mixing ratios of poultry litter and either liquid swine or dairy manure were investigated to determine the feasibility of this technology based on biogas production, methane content in biogas, volatile solids destruction, COD and BOD reduction. Another benefit of co-digesting these wastes is that the potential increase in the substrate C/N ratio can actually help improve the performance of the anaerobic digestion process. The best operating parameters including C/N ratio, temperature, pH, hydraulic retention time, and organic loading rate will also be determined for the digestion process.

Publications

Zhu, J., S. Wu, J. Shen. 2019. Anaerobic co-digestion of poultry litter and wheat straw affected by solids composition, free ammonia, and carbon/nitrogen ratio. J. Environ. Sci. Health Part A 54(3): 231-237.

Shen, J., J. Zhu. 2018. Kinetics of poultry litter in a leach bed reactor with agitation based on two mechanisms: enzymatic hydrolysis and direct solubilization. Biochemical Engineering Journal 135 (15): 115-122.

Shen, J., J. Zhu. 2017. Methane production in an up-flow anaerobic biofilm digester from leachates derived from poultry litter at different organic loading rates and hydraulic retention times. Journal of Environmental Chemical Engineering 5:5124-5130.

Shen, J., J. Zhu. 2017. Modeling the kinetics of anaerobic co-digestion of poultry litter and wheat straw mixed with municipal wastewater in a continuously mixed digester with biological solid recycle using batch experimental data. Chemical Engineering Communications 204(4):501-511.

Hydrogen and methane production by co-digesting liquid swine manure and brewery wastewater in a two-phase system

Animal manure is being produced in increasing amounts due to the rising human population and the parallel increase in quality of life. Manure contains abundant nitrogen, carbon, phosphorus, and ammonia, which can pollute the environment such as water sources, soil, and air. The simplest method to deal with manure is to directly use it as fertilizer. However, the volume of manure produced today is much more than can be utilized as fertilizer. Other methods must be used to accommodate the excess manure. Reactors utilizing anaerobic digestion (AD) can offset manure’s environmental impact by removing much of its harmful substances and producing biogas, which can be used as an alternative energy source to traditional, environment-damaging fossil fuels. Treating manure via AD is a well-established practice, and there are many reports on this technique, including main cattle and poultry manure. While one-phase AD is extensively studied and applied, more recently, researchers have started to investigate two-phase AD operations. A hydrogen-producing dark fermentation phase is followed by a second phase in which the AD process relies on the products of dark fermentation to produce methane. The advantages of this approach include: 1) there are two types of bacteria that are crucial for AD, i.e., acidogenic and methanogenic bacteria. Separating the AD process into two phases allows for the separate cultivation of these two types of bacteria, which thrive at different pH levels and grow at different rates; 2) during the first phase, complex substrates can be efficiently broken down by certain bacteria responsible for hydrogen production, so that in the second phase, i.e., the methanogenic phase, there is more matter readily available to be converted to methane. It was found that a two-phase system yielded more bioenergy than a one-phase system. This process also yields hydrogen gas, which is a cleaner, more efficient energy source than methane, a major benefit of the two-phase process; and 3) it is possible to utilize both products as a combination of methane and hydrogen as a fuel for natural gas-driven vehicles.

Animal manure is being produced in increasing amounts due to the rising human population and the parallel increase in quality of life. Manure contains abundant nitrogen, carbon, phosphorus, and ammonia, which can pollute the environment such as water sources, soil, and air. The simplest method to deal with manure is to directly use it as fertilizer. However, the volume of manure produced today is much more than can be utilized as fertilizer. Other methods must be used to accommodate the excess manure. Reactors utilizing anaerobic digestion (AD) can offset manure’s environmental impact by removing much of its harmful substances and producing biogas, which can be used as an alternative energy source to traditional, environment-damaging fossil fuels. Treating manure via AD is a well-established practice, and there are many reports on this technique, including main cattle and poultry manure. While one-phase AD is extensively studied and applied, more recently, researchers have started to investigate two-phase AD operations. A hydrogen-producing dark fermentation phase is followed by a second phase in which the AD process relies on the products of dark fermentation to produce methane. The advantages of this approach include: 1) there are two types of bacteria that are crucial for AD, i.e., acidogenic and methanogenic bacteria. Separating the AD process into two phases allows for the separate cultivation of these two types of bacteria, which thrive at different pH levels and grow at different rates; 2) during the first phase, complex substrates can be efficiently broken down by certain bacteria responsible for hydrogen production, so that in the second phase, i.e., the methanogenic phase, there is more matter readily available to be converted to methane. It was found that a two-phase system yielded more bioenergy than a one-phase system. This process also yields hydrogen gas, which is a cleaner, more efficient energy source than methane, a major benefit of the two-phase process; and 3) it is possible to utilize both products as a combination of methane and hydrogen as a fuel for natural gas-driven vehicles.

Publications

Xu, S., J. Zhu, Z. Meng, W. Li, S Ren, T. Wang. 2019. Hydrogen and methane production by co-digesting liquid swine manure and brewery wastewater in a two-phase system. Bioresource Technology 293: In press.

Wu, S., L. Chen, J. Zhu, M. Walquist, D. Christian. 2018. Pre-digestion to enhance volatile fatty acids (VFAs) concentration as a carbon source for denitrification in the treatment of liquid swine manure. J. Environ. Sci. Health Part A 53(10): 891-898.

Production of high-value products from broiler litter using solid-state anaerobic digestion and mushroom cultivation

Poultry production in Arkansas requires an average of 44 kWh of electricity and 5.8 gallons of propane and results in the production of approximately 1 ton of litter for every 1000 birds produced. If the litter is only applied in a small, localized area, nutrients can accumulate in the soils to a point that causes eutrophication of local waterways, which can have significant impacts on stream ecology, such as increased algal blooms, and can lead to increased risk to human health related to the production of safe drinking water. However, more value could potentially be added to the waste litter generated by the large poultry industry in Arkansas by exploring alternative uses and treatment processes for this byproduct. Although poultry litter produced in Arkansas is worth approximately $62/ton (on a wet basis) based on nitrogen (N), phosphorus (P), and potassium (K) contents, little to no profit is typically generated by this material due to regulatory restrictions and transportation costs. Therefore, this project is aiming to test the integration of anaerobic digestion and the cultivation of mushroom (P. ostreatus) as a means of utilizing broiler litter with the hypothesis that the cultivation of the fungus on a mixture of wheat straw and broiler litter could serve as a pretreatment to increase the yields of anaerobic digestion by reducing lignin content while also producing edible mushrooms as another high-value product.

Poultry production in Arkansas requires an average of 44 kWh of electricity and 5.8 gallons of propane and results in the production of approximately 1 ton of litter for every 1000 birds produced. If the litter is only applied in a small, localized area, nutrients can accumulate in the soils to a point that causes eutrophication of local waterways, which can have significant impacts on stream ecology, such as increased algal blooms, and can lead to increased risk to human health related to the production of safe drinking water. However, more value could potentially be added to the waste litter generated by the large poultry industry in Arkansas by exploring alternative uses and treatment processes for this byproduct. Although poultry litter produced in Arkansas is worth approximately $62/ton (on a wet basis) based on nitrogen (N), phosphorus (P), and potassium (K) contents, little to no profit is typically generated by this material due to regulatory restrictions and transportation costs. Therefore, this project is aiming to test the integration of anaerobic digestion and the cultivation of mushroom (P. ostreatus) as a means of utilizing broiler litter with the hypothesis that the cultivation of the fungus on a mixture of wheat straw and broiler litter could serve as a pretreatment to increase the yields of anaerobic digestion by reducing lignin content while also producing edible mushrooms as another high-value product.

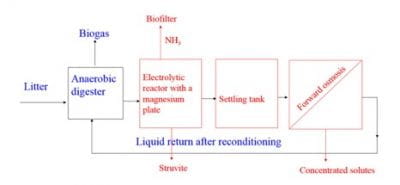

Development of a sustainable treatment system for poultry litter with maximum value recovery

Poultry litter treatment system under study

The long-term goal of this project is to provide the poultry industry in the US a novel anaerobic digestion technology to treat raw poultry litter with minimal water usage to produce not only renewable energy (methane) but also a valuable fertilizer that can be used on farm or transported away to other nutrient deficient areas at reasonable costs. The specific objectives of this proposal include 1) develop and evaluate a specially designed anaerobic digester for loading solid materials and determine the operating parameters that matter most in biogas production and releases of magnesium and phosphate ions when co-digesting poultry litter with an external carbon source such as wheat straw; 2) develop and evaluate an electrolytic reactor with an anodic magnesium plate to produce struvite from the anaerobic digester effluent to remove both nitrogen and phosphorus; 3) develop, evaluate, and compare forward osmosis and a membrane distillation process to further clean up the effluent from the electrolytic reactor so that it can be recycled back to the front for liquefying the feeding poultry litter to the anaerobic digester; and 4) integrate the whole lab-scale system to evaluate its performance in treating poultry litter using the liquid anaerobic digestion technology and the feasibility of commercial applications. The project is funded by the USDA/NIFA/AFRI Foundational and Applied Sciences Program (Program Area Priority: A1531).